Description

This reusable metal system injector is used for introducing any liquid into the low side of a charged hermetic system.

Applications

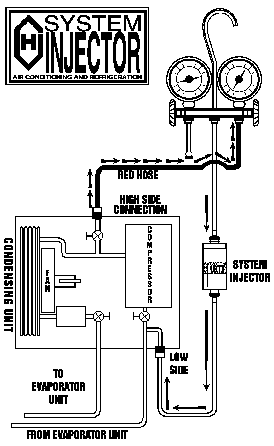

Used with a standard manifold gauge and hermetic systems with a working pressure up to 250 psi.

How to Use

For Introducing Liquid into Low Side of a Charged Hermetic System

Check: Before removing the cap, check for any pressure buildup by depressing the valve core depressor.

Fill: Unscrewing the cap, fill the system injector completely to the top with the liquid to be injected and replace the cap.

Connect: Connect the system injector to the gauge set and purge the lines.

Open Valves: Slowly open valves on the manifold gauge and use refrigerant charge pressure to inject the liquid into the low side of the system.

Store: Always store the system injector with lines removed and cap loose to prevent thread binding and pressure buildup.

Recommended for use with Trace®, Trace2®, Thawzone®, and Acid Neutralizer®.

Reviews

There are no reviews yet.