Latest Products

Our leak detection systems are built to detect leaks reliably and effectively. Locate the hardest-to-find leaks under the toughest conditions. Stop leaks of refrigerant gas in air conditioning and refrigeration systems.

We have top-of-the-line Coil Cleaners, Green Stuff®, Pink Stuff®, and many other products to help keep everything functioning perfectly.

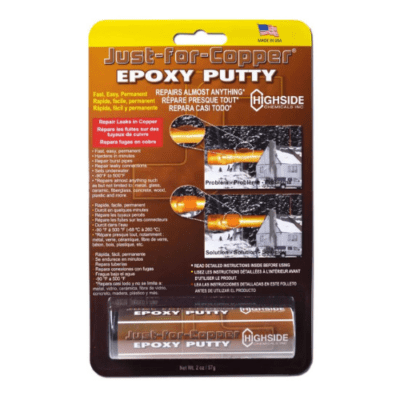

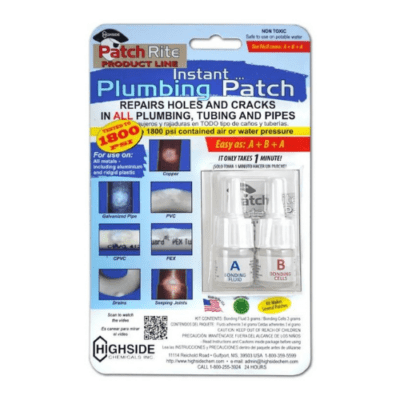

We have the best bonding products like HVAC SuperPro® and Just For Copper®. Our products are at the top of the mind for professionals. Permanent bonding for Copper, Brass, & Aluminum in minutes!

Highside Chemicals, Inc. has manufactured the highest quality chemical products for the maintenance, installation and repair of refrigeration, air conditioning and plumbing systems for over eighty-five years. All products are thoroughly tested and proven to perform to the highest standards. Our commitment to quality along with excellent customer service and technical support makes Highside Chemicals your best choice.